Analytical HRTEM characterization of the high-temperature layered precipitates in VDM Alloy 780 for high-temperature applications

- Abstract number

- 498

- Event

- European Microscopy Congress 2020

- DOI

- 10.22443/rms.emc2020.498

- Corresponding Email

- [email protected]

- Session

- PSA.2 - Metals & Alloys

- Authors

- Dr. Corneliu Ghica (4), Dr. Cecilia Solís (2), Dr. Johannes Munke (2), Dr. Andreas Stark (1), Dr. Bodo Gehrmann (5), Dr. Martin Bergner (3), Prof. Joachim Rösler (3), Dr. Ralph Gilles (2)

- Affiliations

-

1. 3Institute of Materials Research, Helmholtz-Zentrum Geesthacht

2. Heinz Maier-Leibnitz Zentrum (MLZ), TU München

3. Institut für Werkstoffe, Technische Universität Braunschweig

4. National Institute of Materials Physics

5. VDM Metals International GmbH

- Keywords

Alloys; Elemental mapping; HRTEM; Precipitates

- Abstract text

This work contains a combined study using several techniques of analytical electron microscopy meant to clarify the structure of the high-temperature phases formed in a newly developed Ni-base superalloy.

Ni-base superalloys are largely employed nowadays for manufacturing metallic components with excellent mechanical properties at high working temperatures and resistance to corrosive or oxidizing environments, used in gas turbine components for power generation, aircraft propulsion or other related applications. The VDM 780 alloy has been recently developed in a cooperation between Technical University Braunschweig and VDM Metals GmbH [1, 2] in order to push even further the temperature limits of the widely used Alloy 718. VDM 780 is based on the γ matrix (Ni-based cubic Fm-3m structure) and γ’ hardening precipitates (Ni3Al-based cubic Pm-3m structure). In addition, other high-temperature phases may also be present, with potentially important consequences on the mechanical properties of the alloy operating at high temperature [3, 4]. Preliminary investigations by neutron diffraction experiments and synchrotron XRD indicated the presence of two possible phases, the δ-phase (Ni3Nb based orthorhombic Pmmn structure) and/or the η-phase (Ni3Ti hexagonal P63/mmc structure). The amount, size and morphology of the additional precipitated phases, whose nature is not yet completely understood, depend on the particularities of the applied heat treatments [5].

Two samples with the same composition, named hereafter VDM 780-a and VDM 780-b, have been submitted to two different heat treatment protocols in order to study the formation of high-temperature phases in two different situations, namely in the presence or the absence of the γ’ hardening precipitates.

Thin samples have been prepared for TEM investigations by mechanical thinning and ion milling on a Gatan PIPS machine. The samples have been analyzed on a probe-corrected JEM ARM 200F microscope by combining several techniques including SAED, atomic-resolution imaging, chemical characterization by EDS and EELS, elemental mapping by STEM-EDS and STEM-EELS as well as structural modelling.

Synchrotron XRD patterns measured at the P07-HEMS instrument at PETRA III (DESY) together with Rietveld refinements revealed the formation of the γ, and γ’ (only in sample VDM 780-b) phases, as well as the high-temperature η and δ phases. Preliminary SEM observations have revealed the presence of needle-like (actually edge-on plate-shaped) precipitates which could be assigned to the high-temperature phases identified by XRD [6].

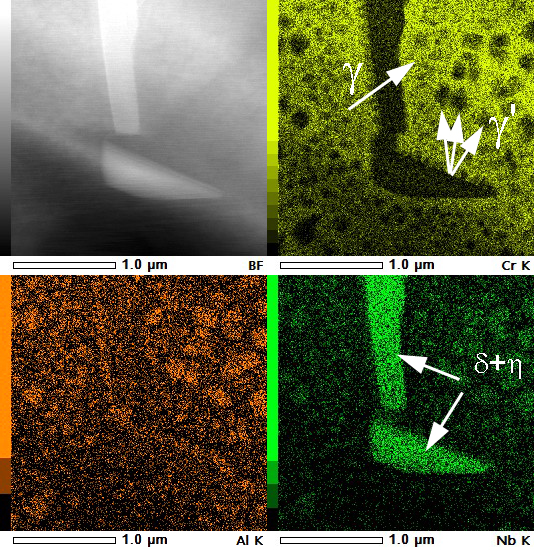

Elemental mapping by STEM-EDS or STEM-EELS and the quantification of the local EDS spectra allowed us to identify the composition and morphology of the γ’, η and δ precipitates with respect to the matrix.

Figure 1. STEM-HAADF image and STEM-EDS elemental maps of Cr, Al and Nb exhibiting the presence of precipitates with different morphologies and chemical compositions in VDM 780.

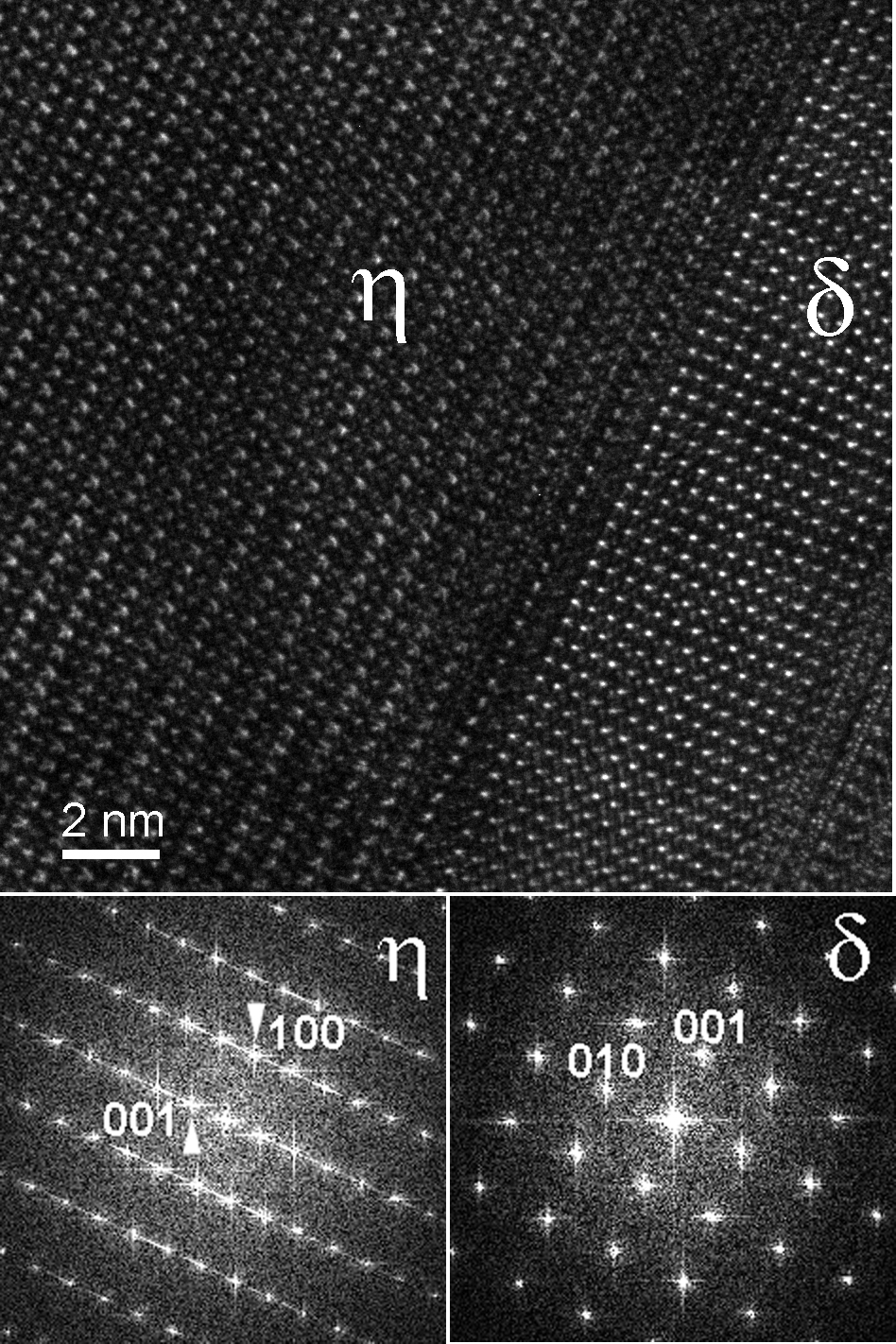

For an in-depth local structural investigations aimed at characterizing the atomic structure and composition of the high-temperature d and/or h precipitates, we combined several techniques of analytical TEM, focusing on edge-on precipitates which could be oriented along main crystallographic axes. TEM images at high magnifications revealed that the plate-like precipitates showed a band-like structure consisting in ribbons with a variable width and contrast, most likely corresponding to two different crystal structures. The SAED patterns from areas including the edge-on precipitates and the matrix can be indexed to reflect the crystallographic relationship between the adjacent phases. In addition, HRTEM imaging and local FFT diagrams have revealed that the high-temperature precipitates in the alloy VDM 780 exhibit a layered structure consisting of alternating δ and η phases in the crystallographic orientation relationship [010]η || [100]δ, (001)η || (010)δ, (100)η || (001)δ. Geometrical Phase Analysis has been used to analyze the strain distribution and the presence of dislocations inside the layered precipitates.

Figure 2. HRTEM image showing different atomic structures inside two adjacent bands forming a typical plate-shaped precipitate within alloy VDM 780; (d) FFT diagrams corresponding to the two adjacent bands of η-phase and δ-phase.

In conclusion, we have unambiguously identified the nature and structure of the high-temperature precipitates in the VDM 780 alloy by combining several techniques of analytical TEM. We have shown that the high-temperature precipitates exhibit a layered structure consisting of alternating δ and η slabs with thicknesses ranging between 2-100 nm, following the crystallographic orientation relationship [010]η || [100]δ, (001)η || (010)δ, (100)η || (001)δ. The thickness of the plate-like precipitates varies from one sample to the other due to the different temperature history. The chemical composition of the d and h stripes shows a deficit of Nb or Ti compared to the nominal stoichiometries of the reference δ and η phases, Ni3Nb and Ni3Ti respectively. This can be attributed, to the occupation of Nb- and Ti-sites by other elements such as Al or the insufficient Nb-supply, due to trapping inside the γ/γ’ phase [7].

- References

[1] T Fedorova et al, 8th International Symposium on Superalloy 718 and Derivatives (2014) p. 587.

[2] J Rösler, T. Hentrich and B. Gehrmann, Metals 9 (2019), 1130

[3] TM Smith et al, Nature Communications 7 (2016), 13434.

[4] M Wang et al, Journal of Alloys and Compounds 701 (2017), p. 635.

[5] C Solís et al, Metallurgical and Materials Transactions A 49 (2018), p. 4373.

[6] C Ghica et al, Journal of Alloys and Compounds 814, (2020) 152157

[7] Financial support of this work via the BMBF Project 05K16WO2 is kindly acknowledged. The authors acknowledge CERIC-ERIC for the access to TEM facilities at NIMP and financial support. CG acknowledges the financial support from Romanian Ministry of Research and Innovation in the frame of the 46 PCCDI project and Core Program PN19-03.