Ca segregation towards an in-plane compressive strain Bismuth Ferrite – Strontium Titanate interface

- Abstract number

- 681

- Event

- Virtual Early Career European Microscopy Congress 2020

- Presentation Form

- Submitted Oral

- DOI

- 10.22443/rms.emc2020.681

- Corresponding Email

- [email protected]

- Session

- PSA.9 - Magnetic and Spintronic Materials

- Authors

- Ulrich Haselmann (1), Georg Haberfehlner (3), Weijie Pei (5), Maxim N. Popov (4), Lorenz Romaner (4), Daniel Knez (2), Jian Chen (5), Arsham Ghasemi (1), Yunbin He (5), Gerald Kothleitner (3), Zaoli Zhang (1, 6)

- Affiliations

-

1. Erich Schmid Institute of Materials Science, Austrian Academy of Sciences

2. Graz Centre for Electron Microscopy

3. Institute of Electron Microscopy and Nanoanalysis, Graz University of Technology

4. Materials Center Leoben Forschung GmbH

5. School of Materials Science & Engineering, Hubei University

6. Institute of Material Physics, Montanuniversität Leoben

- Keywords

atomic resolution TEM, EELS and EDS;

BiFeO3;

density functional theory (DFT);

oxide heterostructure interface;

oxygen vacancy;

segregation;

- Abstract text

In this study, we report the Ca segregation towards an in-plane compressive strain interface between a Bismuth Ferrite thin film and a Strontium Titanate substrate. Transmission electron microscopy (TEM) and scanning transmission electron microscopy (STEM) investigations showed that the Ca had segregated to the interface area initiating structural and electronic changes. These observation results were confirmed via density functional theory (DFT) calculations.[1]

Bismuth Iron Oxide (BiFeO3; BFO) has been a material of great interest in the past years, especially for its multiferroic properties. It is one of the few single-phase multiferroic materials with a coupling of its ferroelectric and antiferromagnetic properties far above room temperature.[2], [3] Since it has been shown, that the magnetic domains can be successfully electrically controlled[2], a new scope of applications opened up, like e.g. memory devices promising superior speed and storage density[4], spintronic devices, spin valves and sensors[5].

A Ca and Mn doped Bi0.98Ca0.02Fe0.95Mn0.05O3 film and for comparison an only Mn doped BiFe0.95Mn0.05O3 film were fabricated with pulsed laser deposition (PLD) on a (100) SrTiO3 substrate using during deposition a substrate temperature of 700°C. Cross sectional TEM samples were prepared by gluing two film pieces together in a Ti holder, afterwards grinding from both sides to a thickness of ≈80µm, dimpling from one side to a residual thickness of 11µm and final thinning with Ar+ ion beam milling. The samples were investigated with x-ray diffraction (XRD), x-ray photoelectron spectroscopy (XPS), TEM, high-resolution transmission electron microscopy (HRTEM), STEM, electron energy loss spectroscopy (EELS) and energy dispersive X-ray (EDX). To support the measurement results DFT calculations have been conducted.

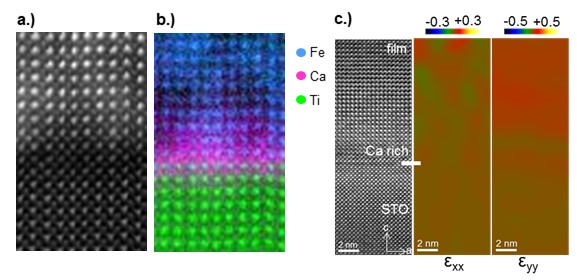

Figure 1. a.) HAADF and b.) EELS spectral image of the interface. c.) HRTEM image with in-plane (εxx) and out-of-plane (εyy) strain of the film received via GPA

STEM investigations of the interface collecting simultaneously EELS and EDX data showed that the Ca was agglomerated at the interface (see Figure 1a,b) . XPS data of the PLD target showed that the Ca level was constant during the deposition. Stopping and range of ions in matter (SRIM) simulations were conducted but didn’t provide any explanation for the Ca agglomeration. In conclusion, the Ca gradient at the interface can only have formed through diffusion of the originally homogenously distributed Ca enabled by the high temperatures during and shortly after the film deposition. The Ca dopant is sitting as expected on the A-site (Bi) position in the perovskite. The Ca is even the majority atomic species with ratio of 60at.% compared to 40at.% Bi on the first A-site layer.

Ca leads to p-type (hole) doping since it provides only two electrons compared to the three of Bi in perovskite. This can either lead to the formation of O vacancies or an oxidation state shift of some cations from Fe3+ to Fe4+. A possible oxidation state shift can be investigated with EELS. [6] However the EELS results show that in the Ca rich interface area no Fe oxidation state shift takes place suggesting that oxygen vacancies are present at the interface. The DFT calculations support this observation since the segregation energy gain is larger, if the formation of oxygen vacancies takes place compared to a shift in the Fe oxidation state. Applying geometric phase analysis (GPA) on the HRTEM images of the interfaces of both film samples shows, that while in the only Mn doped Ca free film the strain increases immediately at the interface, in the film with the Ca agglomeration the out-of-plane strain in the interface region is delayed (see Figure 1c). Combining GPA and intensity analysis of high angular annular dark field (HAADF) images shows a direct correlation between the Ca gradient and the out-of-plane lattice strain. Additionally, the A-site lattice spacing from the HAADF data fit well with the values of the relaxed unit cells from the DFT calculations.

In summary, we have investigated the Ca segregation towards an interface, where the Ca agglomeration leads to a strain reduction. EELS data and DFT calculations indicate the formation of O vacancies in the Ca rich interface. The study presented here is crucial to better understand segregation behaviour, it’s effect on the atomic and electronic structure and how to prevent it, since segregation phenomena can negatively effect the operationality of functional devices. Additionally however, a Ca rich puffer at the interface could prove as counter strategy against the formation of Mn-rich antiphase boundaries at the interface.[7]

- References

[1] Haselmann, U.; Haberfehlner, G.; Pei, W.; Popov, M.; Romaner, L.; Knez, D.; Chen, J.; Ghasemi, A.; He, Y.; Kothleitner, G.; and Zhang, L; ACS Appl. Mater. Interfaces 2020. just published

[2] Zhao, T.; Scholl, A.; Zavaliche, F.; Lee, K.; Barry, M.; Doran, A.; Cruz, M. P.; Chu, Y. H.; Ederer, C.; Spaldin, N. A.; Das, R. R.; Kim, D. M.; Baek, S. H.; Eom, C. B.; Ramesh, R.; Nat. Mater. 2006, 5 (10), 823–829

[3] Catalan, G.; Scott, J. F.; Adv. Mater. 2009, 21 (24), 2463–2485.

[4] Scott, J. F.; Nat. Mater. 2007, 6, 256–257.

[5] Manzoor, A.; Afzal, A. M.; Umair, M.; Ali, A.; Rizwan, M.; Yaqoob, M. Z.; J. Magn. Magn. Mater. 2015, 393, 269–272.

[6] Tan, H.; Verbeeck, J.; Abakumov, A.; Van Tendeloo, G.; Ultramicroscopy 2012, 116, 24–33.

[7] MacLaren, I.; Sala, B.; Andersson, S. M. L.; Pennycook, T. J.; Xiong, J.; Jia, Q. X.; Choi, E. M.; MacManus-Driscoll, J. L.; Nanoscale Res. Lett. 2015, 10, 407.

[8] The financial support by the Austrian Science Fund (FWF): No. P29148-N36 is kindly acknowledged. We want to express our gratitude to the group of Prof. Yunbin He from the Hubei University in the PRC for providing the samples, Gabrielle Felber for help with the sample preparation and Prof. Christian Mitterer and Dipl.-Ing. Martin Rausch for their contribution in the discussion of the deposition kinetics and their help with the SRIM simulations. Additionally we would like to say a big thank you to Dr. Markus Kubicek and Dr. Markus Katzer for the fruitful discussions.