Correlative 3D characterization of hierarchical zeolite structures linking nano X-ray tomography and 360° electron tomography

- Abstract number

- 859

- Event

- European Microscopy Congress 2020

- DOI

- 10.22443/rms.emc2020.859

- Corresponding Email

- [email protected]

- Session

- PSA.5 - Nanoparticles & Catalysts

- Authors

- Dominik Drobek (2), Benjamin Apeleo Zubiri (2), Janis Wirth (2), Silvan Englisch (2), Tobias Weißenberger (1), Wilhelm Schwieger (1), Erdmann Spiecker (2)

- Affiliations

-

1. Chair of Chemical Reaction Engineering, University of Erlangen-Nuremberg, Egerlandstr. 3

2. Institute of Micro- and Nanostructure Research (IMN) & Center for Nanoanalysis and Electron Microscopy (CENEM), Friedrich‐Alexander‐Universität Erlangen‐Nürnberg, Interdisciplinary Center for Nanostructured Films (IZNF), Cauerstr. 3

- Keywords

360° electron tomography, 3D, correlative microscopy, hierarchial material, nano X-ray tomography

- Abstract text

In catalysis, the available total surface area for active sites is of utmost importance and the intraparticle pore space of a single particle has to be designed accordingly. In addition, the interparticle pore space, determining the packing density of a particle network, is also critical for catalytic applications. MFI-type zeolite particles exhibit such a structured pore system and can serve as support frameworks for catalytic applications. Applying multiscale Nano-X-ray tomography (Nano-CT) and 360° electron tomography (ET) reveals the complex morphology of a single MFI-type zeolite particle and even larger agglomerations of these particles can be analyzed in detail [1].

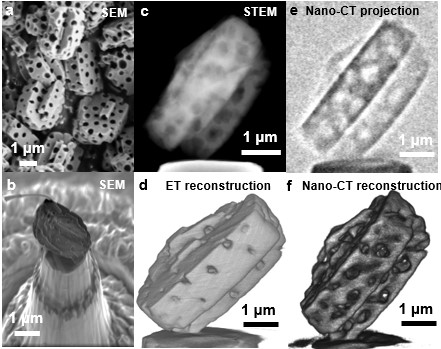

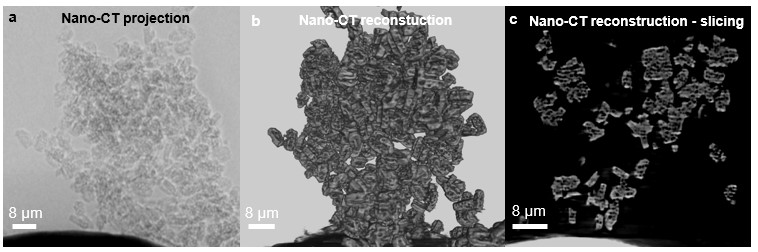

The combination of 360° electron tomography with lab-based high-resolution X-ray tomography featuring Fresnel Zone Plate and Zernike Phase ring optics allows three-dimensional (3D) imaging of complex material structures across multiple length scales. Here, we investigate MFI-type zeolite particles with sizes up to 3 µm featuring a network of interconnected macropores [2]. Combining the advantages of both techniques, ET and Nano-CT, enables detailed investigation of single particles as well as extended particle agglomerates regarding their intraparticle and interparticle pore spacings. ET being better suited for single particles due to the higher resolution enables imaging with a high resolution down to a few nm but suffers from the limited sample volume of a few microns due to the inelastic scattering of the electrons in the sample volume. Nano-CT, on the other hand, is perfectly suited for analyzing larger particle clusters with a maximum field of view (FOV) of 64 µm but suffers from a limited resolution of 50 nm.

MFI-type zeolite crystals are synthesized via steam-assisted-crystallization transformation (SAC), where the MFI-type zeolite structure evolves from mesoporous silica sphere (MSP) primary particles, which functions as a macropore template. The porous framework with its high specific surface area and interconnected pore system provides an ideal model system to demonstrate the benefit of combining ET and Nano-CT to visualize the morphology at different stages of the crystallization process.

Combining a FEI Titan Themis 300 for ET at 300 kV in high-angle annular dark-field (HAADF) scanning transmission electron microscopy (STEM) mode and a Zeiss Xradia 810 Ultra in phase-contrast mode with a 5.4 keV Cr source for Nano-CT enables a complete 3D-reconstruction of the pore structure, quantitative analyses and, in particular, a direct comparison of the 3D-imaging techniques themselves. The zeolite particles were individually selected and transferred to the top of tailormade tips, utilizing a novel stamping transfer technique in a dual-beam FEI Helios NanoLab 660 scanning electron microscope (SEM) / focused ion beam (FIB) instrument, to deliver optimal imaging conditions [3].

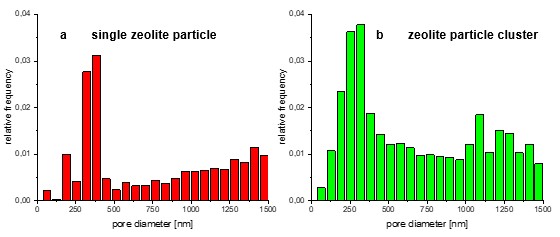

Applying Nano-CT and 360° ET to the same macroporous zeolite sample illustrates perfectly the interlocking of both techniques. Exploiting the higher resolution of ET, the intraparticle morphology, i.e. the internal pores and their interconnectivity, and even the pore formation during the transformation process can be nicely revealed. Additionally, the ET datasets can serve as input for thresholding of the Nano-CT data. In contrast, Nano-CT imaging enables the analysis of larger particle agglomerates (cf. Fig. 2) due to its larger field of view, thereby improving statistical relevance. Furthermore, the interparticle and intraparticle pore space can be analyzed in detail (cf. Fig 3) showing the expected pore size range for both samples (Fig. 3a & 3b). For the embedded macropores it is around 200-500 nm and the interparticle pore space starts above 1 µm of the zeolite particle cluster (Fig. 3b).

Acknowledgment:

We gratefully acknowledge the German Research Foundation (DFG) for funding through the priority program SPP 1570, the Collaborative Research Centre 1411 “Design of Particulate Products”, the research training group GRK1896 “In situ Microscopy with Electrons, X-rays and Scanning Probes” and the project SP648/8 “High-resolution X-ray microscopy for correlative tomography, high throughput screening and in situ mechanical testing of structural and functional materials”.

Figure 1. (a) SEM image of a bunch of completely crystallized macroporous zeolite particle. (b) SEM image of a transferred zeolite particle on a tailored tip. (c) HAADF STEM image from the 360° ET tilt series (d) Volume rendering of the 3D ET reconstruction. (e) Phase contrast image from the Nano-CT tilt series of a macroporous zeolite particle. (f) Volume rendering of the 3D Nano-CT reconstruction.

Figure 2. (a) Phase contrast image from the Nano-CT tilt series of a macroporous zeolite particle cluster on a tip. (b) Volume rendering of the Nano-CT reconstruction. (c) Slice through the 3D reconstruction showing the resolved internal macropores of each single zeolite particle.

Figure 3. (a) Pore size distribution of a single fully crystallized zeolite particle with a broad peak around 375 nm. (b) Pore size distribution of a fully crystallized zeolite particle cluster with a broader peak around 200-400 nm and a second peak region above 1 µm.

- References

[1] Apeleo Zubiri, B., et al., Scale-Bridging 3D Analysis of Micro-/Macroporous Zeolite Particles Using X-Ray Nano-Tomography and Electron Tomography. Microscopy and Microanalysis 25(S2) 396-397, 2019.

[2] A.G. Machoke et al., Adv. Mater. 27 (6) 1066-1070, 2015.

[3] T. Przybilla et al., Small Methods 2, 1700276, 2018.