Investigation of superconducting Ba(Fe,Co)2As2 thin films on CaF2

- Abstract number

- 67

- Event

- Virtual Early Career European Microscopy Congress 2020

- Presentation Form

- Submitted Oral

- DOI

- 10.22443/rms.emc2020.67

- Corresponding Email

- [email protected]

- Session

- PSA.9 - Magnetic and Spintronic Materials

- Authors

- Lukas Grünewald (2), Marco Langer (1), Sven Meyer (1), Jens Hänisch (1), Bernhard Holzapfel (1), Dagmar Gerthsen (2)

- Affiliations

-

1. Karlsruhe Institute of Technology (KIT) - Insitute for Technical Physics (ITEP)

2. Karlsruhe Institute of Technology (KIT) - Laboratory for Electron Microscopy (LEM)

- Keywords

electron microscopy, iron-based superconductor, thin film

- Abstract text

Fe-based superconductors are unconventional high-temperature superconductors with maximum transition temperatures (Tc) in the range of 58 K and high, nearly isotropic upper critical fields at low temperatures [1]. Besides their fundamental properties, Fe-based superconducting thin films [2] are of interest for applications such as superconducting tapes [3]. Among this material class, Co-doped BaFe2As2 (Ba122) is an intensively studied material system. Ba122 films on CaF2 are of particular interest due to their high Tc values compared to Ba122 on other substrates [2]. However, the growth mechanisms of Ba122 thin films deposited by pulsed laser deposition (PLD) are still not fully understood due to the influence of various fabrication parameters and possible interactions with the substrate. For example, earlier work on Ba122 on CaF2(001) substrates showed considerable differences in Tc and microstructural properties when varying the deposition rate during Ba122 thin film during growth [4]. Microstructural defects can be indeed beneficial for an enhancement of the critical current density by acting as pinning centers for emerging magnetic vortices in the Shubnikov phase. Therefore, the intentional addition of pinning centers, e.g., in the form of nanoparticles, is of interest [5].

In this work, we have analyzed the microstructural changes of Ba122 on CaF2 in dependence of the deposition rate and the addition of nanoparticles (denoted as nanocomposite films) by analytical transmission electron microscopy. Ba(FexCo1-x)2As2 thin films with Co doping x = 0.08 were deposited on heated (700 °C), single-crystalline CaF2(001) substrates by PLD. The Ba122 deposition rate was controlled by varying the laser pulse fluence [4] between 4.8 J/cm2 (high deposition rate of 0.9 Å/s) and 1.2 J/cm2 (low deposition rate of 0.4 Å/s). Nanocomposite thin films were grown by an intermittent exchange of the Ba122 target with targets of other compositions (e.g. BaHfO3) during PLD [5]. Cross-section samples were prepared by focused-ion-beam milling using the in-situ lift-out technique. (Scanning) transmission electron microscopy ((S)TEM) in combination with electron energy loss and energy-dispersive X-ray spectroscopy (EELS/EDXS) was used to investigate the microstructure and chemical properties. Multivariate analysis algorithms were applied to enhance the signal-to-noise ratio in spectrum images and for crystal structure analysis based on Fourier-transformed (FT) high-resolution TEM images [6].

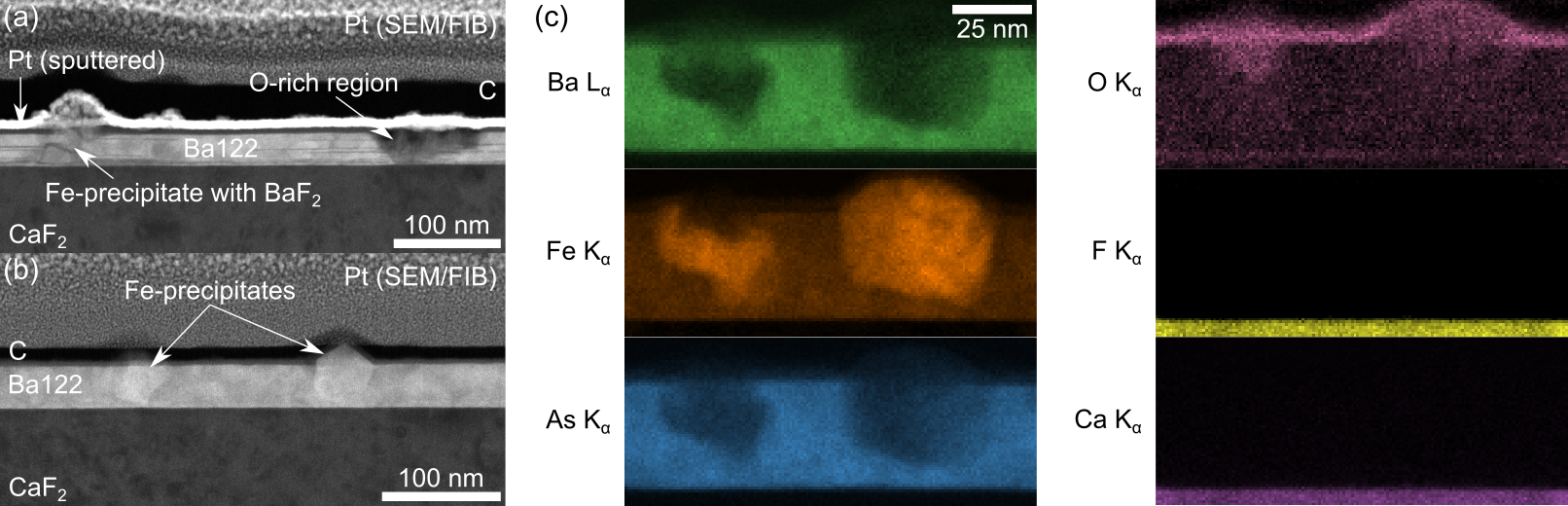

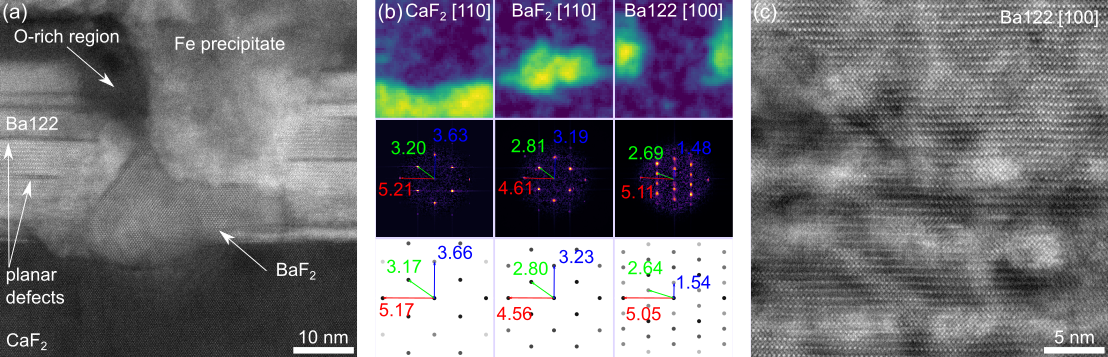

Epitaxial growth of Ba122 on CaF2 is observed for all investigated samples (Fig. 1a,b). For the slower deposition rate (Fig. 1a) more defects and secondary phases are observed compared to faster deposition (Fig. 1b). Planar defects show dark contrast in high-angle annular dark-field (HAADF) STEM images (Fig. 1a, 2a). Fe-rich precipitates were identified by STEM-EDXS (Fig. 1c) and are observed in all samples. Other secondary phases, i.e. BaF2 and an O-rich phase (Fig. 1a, 2a), are only detected for Ba122 grown at a low rate. FT analysis in combination with non-negative matrix factorization (NMF, [6]) shows that BaF2 forms at the interface to CaF2 and also penetrates into the substrate (Fig. 2a and Fig. 2b uppermost row). A comparison of the NMF factor loadings (i.e. FTs in the middle row of Fig. 2b) with simulated diffraction patterns (bottom row of Fig. 2c) shows good agreement with the proposed crystalline phases. Fe precipitates are often observed in combination with an O-rich region and BaF2 (Fig. 2a). In addition, EELS analysis reveals the presence of F in the slowly grown layer. HAADF-STEM imaging of a nanocomposite Ba122-BaHfO3 sample shows strong contrast variations which are indicative of strain and a local change in the mean atomic number caused by nanoparticles embedded in the Ba122 matrix (Fig. 2c).

To conclude, we found considerable differences in Ba122 layer growth on CaF2(001) substrates depending on the deposition rate. The formation of BaF2 is suppressed at high deposition rates and fewer planar defects are present. Overall, the fast-grown film shows better homogeneity. However, the measured Tc value (Tc,90 = 27 K, i.e. 90% of normal state resistance) is higher for the slowly grown sample, which may be due to a difference in residual strain between the two thin films. Inhomogeneous contrast indicates that intermittent deposition of BaHfO3 during growth leads to the formation of nanoparticles in the Ba122 matrix. Their spatial distribution and effect on the superconducting properties are currently under investigation.

Figure 1: HAADF-STEM overview images of layers grown with (a) low and (b) high laser fluence, i.e. slower/faster layer growth, respectively. More defects and precipitates are visible in the slowly grown sample. (c) Qualitative elemental maps from the sample shown in (b) obtained by STEM-EDXS. The precipitates are Fe rich and an oxidized surface layer is observed.

Figure 2: (a) HAADF-STEM image of a typical defective region from the sample grown with a slow deposition rate. (b) Corresponding FT analysis from the image shown in (a) obtained by NMF. Score maps in the uppermost row indicate the spatial distribution of the NMF loadings (here FTs) in the middle row. The bottom row shows simulated diffraction patterns. All values are given in nm-1. (c) HAADF-STEM image of a Ba122-BaHfO3 nanocomposite film. The visible contrast variations are indicative of strain and suggest the presence of nanoparticles in the Ba122 matrix.

- References

[1] H. Hosono et al., Mater. Today 21 (2018), 278–302

[2] J. Hänisch et al., Supercond. Sci. Technol. 32 (2019), 093001

[3] K. Iida et al., Appl. Phys. Rev. 5 (2018), 031304

[4] M. Langer et al., J. Phys. Conf. Ser. 1293 (2019), 012014

[5] S. Meyer et al., J. Phys.: Conf. Ser. (2020), in press

[6] B.R. Jany et al., Micron 130 (2020), 102800