Investigation of TRIP Steel by Advanced Microscopy Techniques

- Abstract number

- 573

- Event

- European Microscopy Congress 2020

- DOI

- 10.22443/rms.emc2020.573

- Corresponding Email

- [email protected]

- Session

- PST.5 - Diffraction techniques and structural analysis

- Authors

- Naděžda Vaškovicová (1), Libor Novák (2), Šárka Mikmeková (1)

- Affiliations

-

1. Institute of Scientific Instruments of the Czech Academy of Sciences, Královopolská 147, 612 64

2. Thermo Fisher Scientific, Vlastimila Pecha 1282/12, 627 00

- Keywords

Ga ions interaction, in situ heating, martensite - austenite transformation, retained austenite, TRIP steel

- Abstract text

This research is a new approach in TRIP steel sample examination, completely prepared, affected and analysed in the scanning electron microscope. Retained austenite phase was investigated by the backscatter electrons (BSE) imaging and the electron backscatter diffraction (EBSD) technique.

The DualBeam focused ion beam-scanning electron microscope (FIB-SEM) Helios G4 HP with special accessories and a novel equipment is a powerful tool for many new experiments. Small piece of a sample can be tested on a structural characterization by standard signal electrons detectors and subsequently the area of interest can be used for more innovative research techniques for the materials science. The objectives of this study are interaction Ga ions with surface of the sample; the transmission EBSD (t‑EBSD) phase analysis of lamellas lifted out from the selected area and investigation of heat-induced phase transformation with more sophisticated tools, such as a micro‑heater.

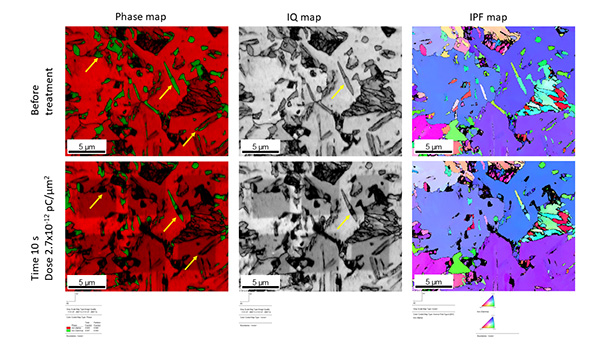

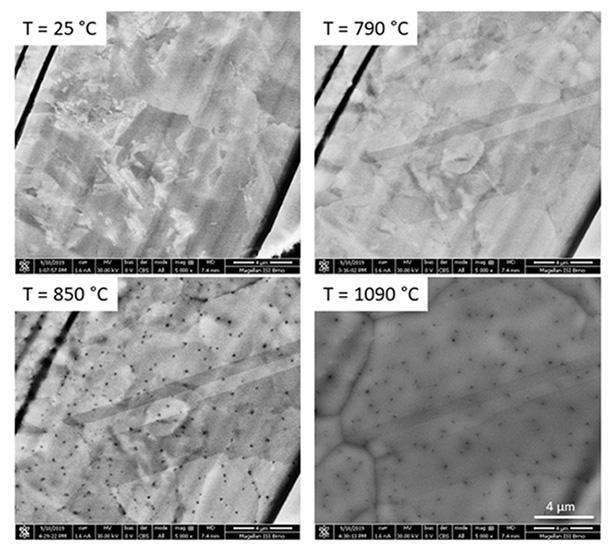

The areas of interest were localized by BSE imaging, by using the concentric backscatter (CBS) detector. The level of damage caused by interaction of Ga ions with the TRIP steel was evaluated by the EBSD (EDAX) analysis of the area before treatment and after, both on the same experimental conditions (i.e. magnification 5000x, accelerating voltage 20 kV, beam current 6.4 nA, step size 50 nm). The dose of Ga ions depends on time of exposure, size of ion irradiated area, ion beam current and voltage (dose 2.7x10-12 pC/µm2, time 10 s, area size 5x5 um, voltage 8 kV and current 5.7 pA for presented experiment). Chunk of the TRIP steel of 50x50 µm size with FIB polished upper side was situated on a MEMS chip in µHeater holder (Thermo Fisher Scientific) and heated up from 25°C to 1090°C. The effect of heating on the TRIP steel microstructure was documented by the BSE imaging (voltage 30 kV and current 1.6 nA in the shown experiment).

The initial experiments of the interaction of Ga ions with the TRIP steel surface show instability of the retained austenite and its extremely fast transformation on martensite. Low ion dose and time of exposure have unexpectedly strong effect on the austenite grains, as demonstrated in Figure 1. This results lead us to caution during the finalization of the lamellas and the FIB polishing of the viewing side for the 3D EBSD technique, concurrently draw attention to possible changes in the structure of the material during milling chunks and the depth of this transformation by using standard FIB setting for milling (30 kV, 21 nA).

Figure 1. Interaction of Ga ions with TRIP steel. Yellow arrows mark γ-austenite grains transformed on martensite in the exposed areas.

The test of the martensite ‑ austenite transformation (Figure 2) by heating up the chunk of TRIP steel determined temperature 760°C, on which the structural changes occurred. However, more tests and simulations are required for detailed specification of material transformation.

Figure 2. In-situ heating of the TRIP steel sample placed on the MEMS chip.

The challenge for the following tests is to find the operating conditions that correspond to non‑transformation of austenite on martensite phase, together with fine polishing of the material as a finalization of lamellas, chunks and scanning area for the 3D EBSD. On the other hand, the heat‑induced processes of grains and phases transformation and the tool holding a stable heating conditions suitable for forming steel microstructure, open new possibilities for experimental improvement of TRIP steel properties and their application in the industry.

- References

We acknowledge financial support from the TN01000008 project of the Technology Agency of the Czech Republic, Strategy AV21 of The Czech Academy of Sciences and CEITEC Nano Research Infrastructure supported by MEYS CR (LM2018110).