Magnetic structure of low-alloyed steel – Correspondence between electron microscopy and Barkhausen noise measurements

- Abstract number

- 759

- Event

- European Microscopy Congress 2020

- DOI

- 10.22443/rms.emc2020.759

- Corresponding Email

- [email protected]

- Session

- PSA.8 - Microscopy in industrial applications

- Authors

- Mari Honkanen (1), Suvi Santa-aho (1), Minnamari Vippola (1)

- Affiliations

-

1. Tampere University

- Keywords

Barkhausen noise, magnetic material, SEM, TEM

- Abstract text

Introduction

The structure of ferromagnetic material can be characterized by its microstructural and magnetic features. Besides the microstructure, the magnetic features are influenced by external conditions such as applied or residual stresses. One magnetic non-destructive testing (NDT) method is Barkhausen noise (BN) which is a commonly used quality control method for e.g. power transmission components after heat treatment and grinding. The most valuable benefits of the BN method are its non-destructive nature and ability to indicate a defect formation on the surface layer during manufacturing. The features of BN are very sensitive to the sample microstructure, stress, and material properties. BN is generated by the motion of the magnetic domain walls within the sample when it is placed in a time-varying external magnetic field. Domain wall movements are hindered by microstructural features: phase or grain boundaries, dislocations, precipitates etc. A domain structure is the most important factor determining how the magnetization and the stresses are related to each other. The applied mechanical stresses influence the domain walls by effective pressure: 180° domain walls are not influenced because pressure is affecting in opposite directions on both sides of the wall, whereas the 90° domain walls are stress sensitive [1]. Even if BN is widely used in the industrial quality control procedures, the link between the microstructure of the sample and the properties of the BN signal remains not fully understood. Here, we combine magnetic structural characterization carried out by TEM and SEM with BN measurements to improve the understanding of how these features of the sample are manifested in the properties of the ensuing BN.

Materials and Methods

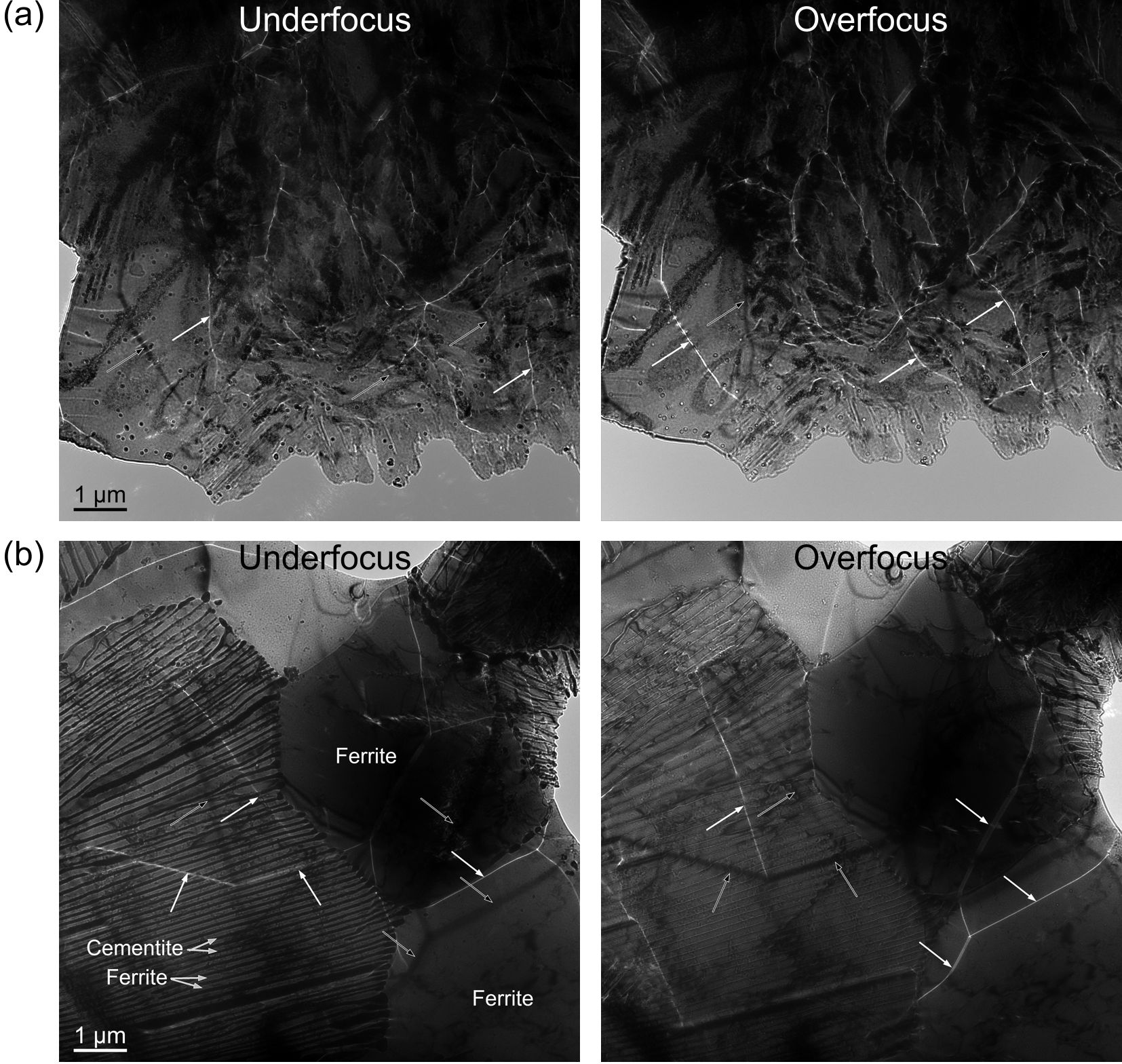

Industrial, low-alloyed steel (CF53) after different heat-treatments, resulting in a martensitic and pearlitic structures, was studied. Microstructural features and magnetic domains were characterized by TEM. Domain wall imaging was done in Lorentz mode: adjoining magnetic domains cause different deflections for incident electrons producing contrast to the image. Magnetic domains were studied also by SEM: a forescatter electron detector (FSD) attached to the EBSD detector was used to image them. SEM+EBSD enables collection of crystallographic and magnetic domain information at the same time. Magnetic behaviour of the same martensitic and pearlitic structures was studied by Barkhausen noise measurements.

Results and Discussion

Highly strained martensite has a high dislocation density and hardness and pearlite is two-phased (ferrite and cementite) with a lamellar structure and lower hardness compared to martensite (Fig. 1). Based on the electron microscopy results, the pearlitic steel had larger domain size compared to the martensite (Fig. 1). These different microstructures caused a dissimilar BN response. Varying microstructure state in martensitic and pearlitic steel resulted a diverse BN response. According to the hardness, the hard martensitic structure should have a low BN response, however, the observed BN response from pearlite was lower. The mechanisms of domain wall motion are complex. The pinning strengths of different obstacles may vary and therefore, the effect of magnetic substructure on the BN measurement is different. Our further studies provide information of the 90° and 180° wall distribution in both martensitic and pearlitic structures. Additional electron microscopy studies will be carried out to still improve the understanding of how microstructural and magnetic features of the sample contribute to the BN response.

Figure 1. TEM images in Lorentz mode of the (a) martensitic and (b) pearlitic structure of low-alloyed steel CF53. Domain walls (marked by white and black arrows) are visible in underfocus and overfocus images (Fresnel mode).

Conclusions

BN is widely used in the industrial quality control procedures, however, the effects of material characteristics to the properties of the BN signal is not fully understood. Our approach was to combine micro- and magnetic structural characterization by electron microscopy with BN measurements to indicate the magnetic behaviour of steel. In this way, we can achieve a new level of understanding how material features act on the BN response.

- References

[1] B Cullity and D Graham, Introduction to magnetic materials (Wiley-IEEE Press, USA)