Nanoscale temperature measurement in an operating MEMS gas nanoreactor using Al plasmon nanothermometry

- Abstract number

- 822

- Event

- European Microscopy Congress 2020

- DOI

- 10.22443/rms.emc2020.822

- Corresponding Email

- [email protected]

- Session

- PST.6 - In-situ and in-operando microscopy

- Authors

- Dr Adrian Chmielewski (1), Prof. Christian Ricolleau (1), Dr Damien Alloyeau (1), Dr Jaysen Nelayah (1)

- Affiliations

-

1. Materials and Quantum Phenomena

- Keywords

In situ TEM

Volume expansion of metal

Volume plasmon shift

Electron Energy Loss Spectroscopy

Local temperature determination

- Abstract text

Summary

Method for local temperature measurement in an operating MEMS nanoreactor by following the energy shift of aluminium volume plasmon under vacuum and gas environment as a function of temperature using EELS.

Introduction

Temperature is a key factor in material science as it influences the state and properties of matter. Over recent years, temperature controlled in situ TEM employing MEMS microheater has emerged as a powerful technique to study the effects of heat stimuli on the states and properties of matter during solid-solid, solid-liquid and solid-gas interactions. To unambiguously relate temperature effects on material structure or properties, it is imperative that the local temperature of the sample is known with high accuracy during temperature controlled TEM observations. In a TEM, this remains extremely challenging due to the high spatial confinement of the reactive environment and sample, making it impossible to deploy traditional thermometry methods. In this contribution, we present the use of aluminium plasmon-based thermometry, proposed recently [1], to assess the performances of the SiC heater of MEMS-based gas nanoreactors. For this, we have measured the differences between the setpoint temperature provided by ex situ calibration of the heater using optical pyrometry and the experimentally-determined local temperature and evaluated the spatial and temporal uniformities of the local temperature [2].

Material and methods

The gas nanoreactor used is provided by Protochips Inc and is a prototype of Protochips Atmosphere gas holder. It is devoid of the closed loop temperature control of the SiC heater which is a standard feature of the latter and which ensures, independently of the gas environment prevailing in the nanoreactor, a temperature accuracy of more than 95 % and a temperature uniformity of the order of 99.5 % as per Protochips specifications. Al nanoparticles (NPs) with an average diameter of about 50 nm were used as local temperature probes. The NPs were dry-deposited on the SiN film of the heating environmental chip prior to in situ experiments. The temperature dependence of the volume plasmon of aluminium nanospheres was obtained at single particle level using spatially and time-resolved low-loss electron energy spectroscopy (STEM-EELS). STEM-EELS analyses were performed with a JEOL ARM 200F TEM equipped with an aberration corrector of the objective lens and a cold FEG electron source operated at 200 kV.

Results and discussion

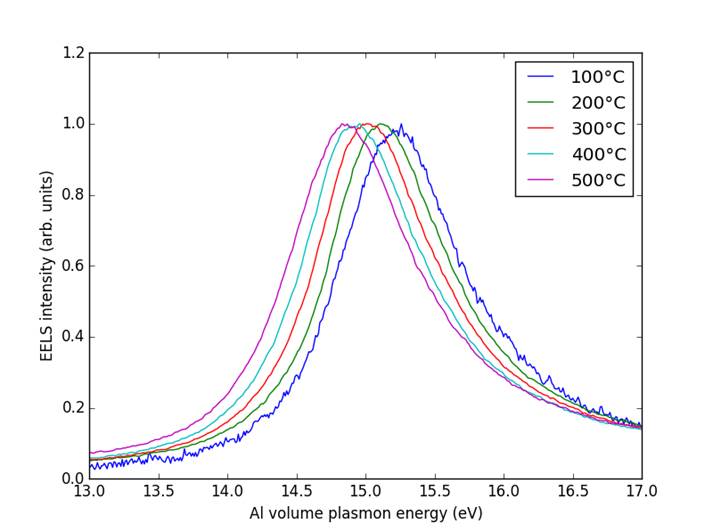

Figure 1 shows a temperature serie of EEL spectra at the volume plasmon peak of an alumunium NP heated in vacuum at setpoint temperatures between 100 and 500°C. As predicted by free-electron model, a redshift of the volume plasmon with temperature is observed.

Figure 1: EEL spectra acquired at the volume plasmon of a single Al nanoprobe heated between 100 and 500 °C. The Al volume plasmon redshifts with increasing temperature.

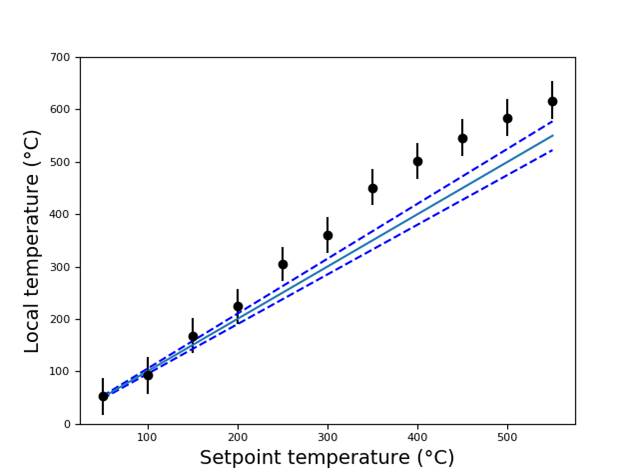

Figure 2 compares the average local and the setpoint temperatures during heating between room temperature and 550 °C in vacuum. The local temperature coincides with the setpoint temperature up to 200 °C. Above, the local temperatures are higher than setpoint temperatures.

Figure 2: Comparison between local (black dots) and setpoint temperatures (blue lines) in a MEMS-based nanoreactor from Protochips Inc. operating under vacuum between 24 and 550 °C. The dashed lines represent the upper and lower setpoint temperature considering the 95 % accuracy on the setpoint temperatures as per Protochips specifications.

Assessment of the spatial and temporal uniformities of the local temperature has been performed shows that while the temporal stability of the local temperature is extremely high, subtle variations of the local temperature across the heater region occur. Taking advantage of the absence of an active temperature control on the heating system of the nanoreactor, we have also established the pressure dependence of the local temperature in a closed nanoreactor upon introduction of static hydrogen gas. Temperature comparisons performed both under vacuum and in the presence of a static H2 gas environment confirm that the local and setpoint temperature can be different in an operating gas nanoreactor.

Conclusion

The methodology presented for local temperature measurement is versatile as it can be implement during any thermal TEM studies (using either MEMS microheaters or traditional furnace-type holders). Moreover, it is easy to implement albeit the presence of an EELS spectrometer on the microscope. It joins the small set of approaches that enable local temperature measurement during temperature controlled in situ TEM.

- References

[1] M. Mecklenburg, W. A. Hubbard, E. R. R. White, Dhall, S. B. Cronin, S. Aloni, B. C. Regan, Nanoscale temperature mapping in operating microelectronic devices, Science 347 (622) (2015) 629-632.

[2] A. Chmielewski, C. Ricolleau, D. Alloyeau, G. Wang and J. Nelayah

Nanoscale temperature measurement during temperature controlled in situ TEM using

Al plasmon nanothermometry, Ultramicroscopy, 209, 2020.