Radiation-induced formation of gas bubbles in beryllium after neutron irradiation with up to 36 dpa

- Abstract number

- 590

- Event

- European Microscopy Congress 2020

- DOI

- 10.22443/rms.emc2020.590

- Corresponding Email

- [email protected]

- Session

- PSA.2 - Metals & Alloys

- Authors

- Dr. Michael Klimenkov (1), Ute Jäntsch (1), Dr. Pavel Vladimirov (1), Nikolai Zimber (1), Dr. Michael Rieth (1)

- Affiliations

-

1. Karlsruhe Institute of Technology

- Keywords

neutron irradiation, helium bubble, tritium, swelling, precipitates

- Abstract text

The current interest in the mechanical properties and microstructure of neutron-irradiated beryllium relates to its planned application in the Helium-Cooled Pebble Bed (HCPB) European concept of a breeding blanket of DEMO [1]. Irradiation experiments in high-neutron-flux nuclear research reactors yield information about microstructural evolution of beryllium under conditions relevant to fusion (temperature, damage dose, helium and tritium productions). The HIDOBE-02 irradiation campaign carried out at the HFR, Petten where beryllium was irradiated at the temperature range from 410°C to 680°C. The evolution of cavities caused neutron irradiation at different temperatures was investigated using transmission electron microscopy (TEM). The target preparation of the samples was performed with a focused ion beam (FIB).

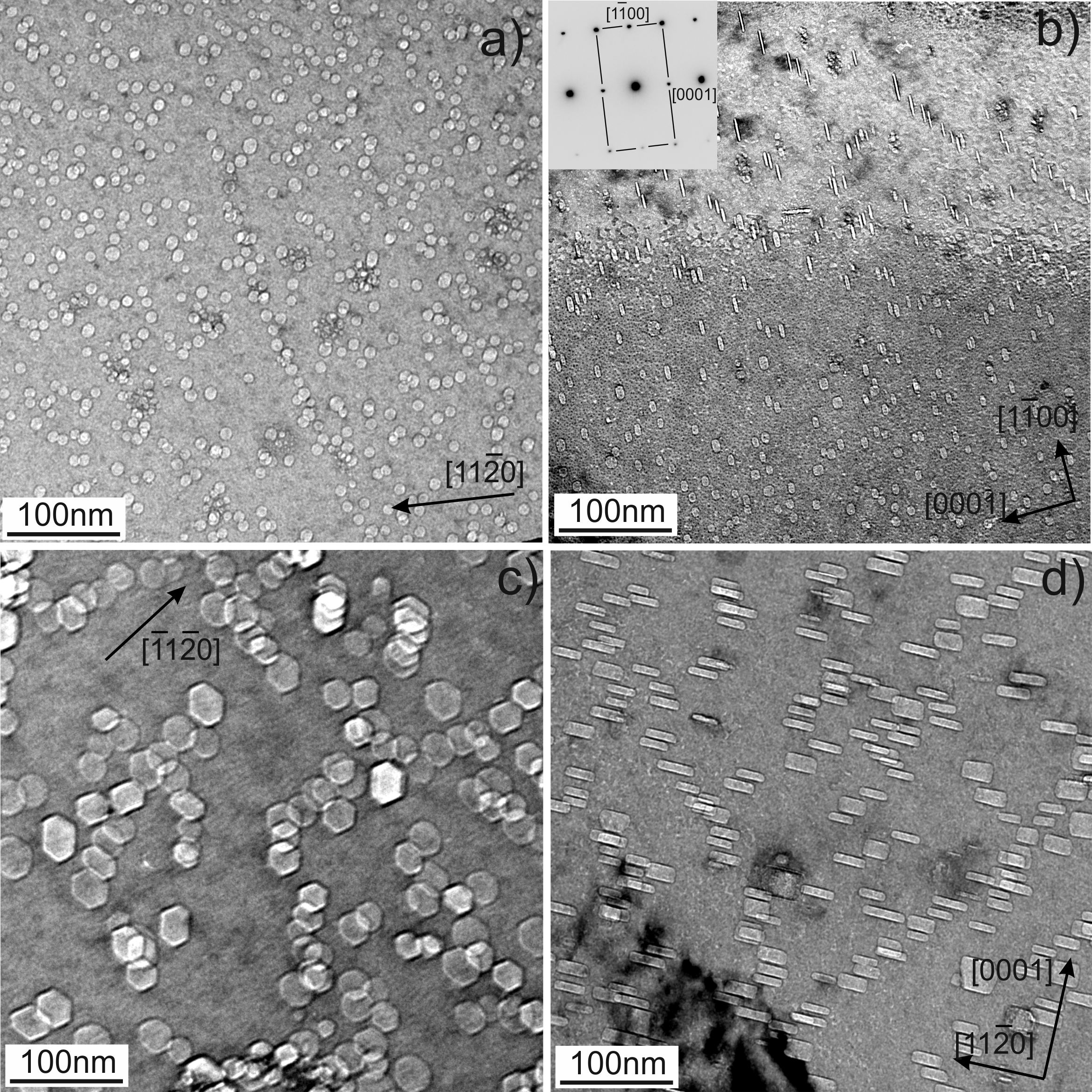

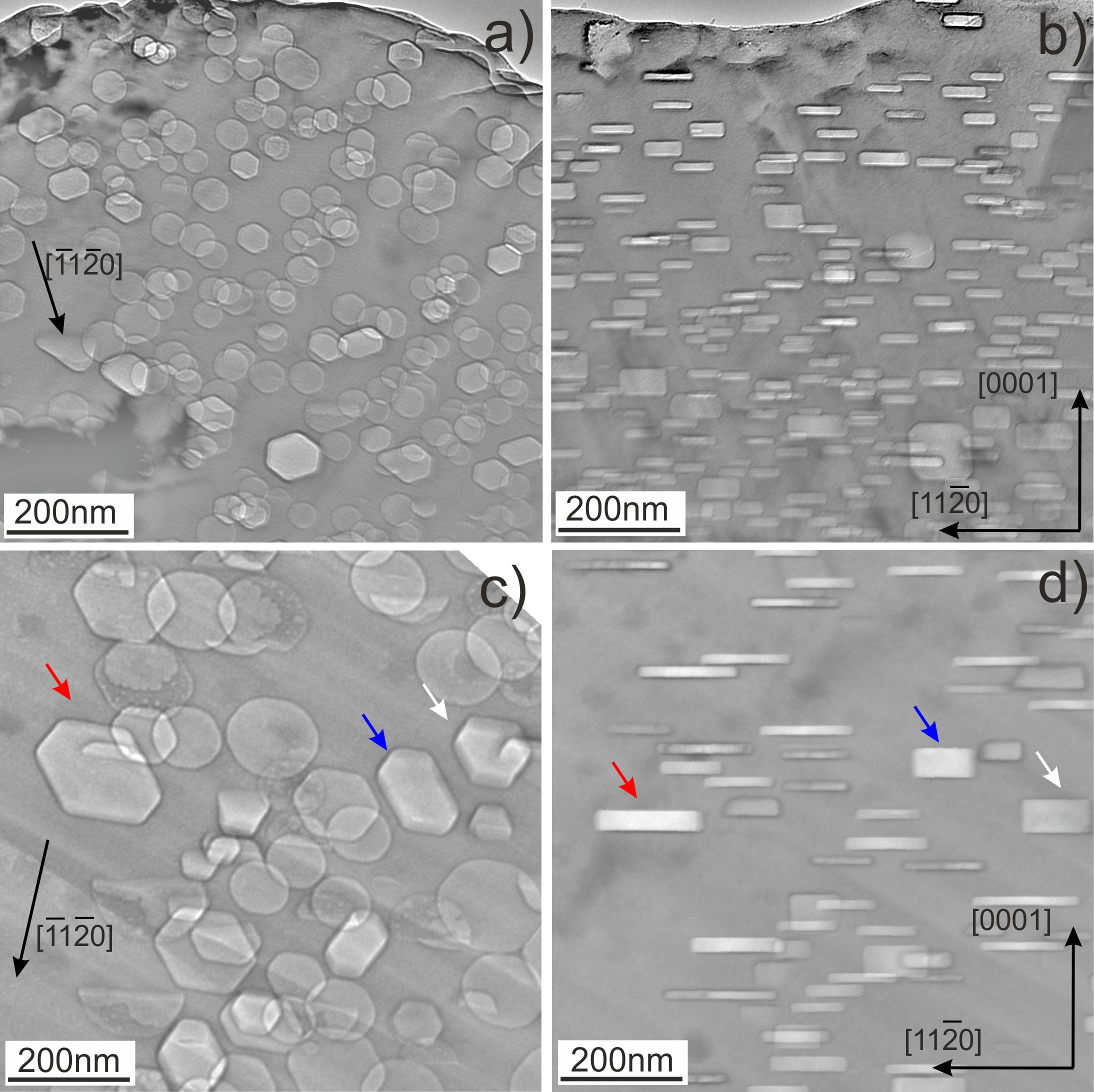

Typical for the intragrain microstructure of irradiated beryllium is the formation of gas bubbles, as shown in Fig. 1, 2. The bubbles observed after irradiation at the lowest irradiation temperature of 643 K (370 °C) (Fig. 1a) have a size of ca. 10 nm with a round or slightly faceted shape. Tilting of the lamellae does not reveal any anisotropy in the shape of bubbles inside grains, suggesting that their shape is close to spherical. In contrast to the lowest temperature, bubbles grown at higher temperatures have a pronounced hexagonal prismatic shape with their bases located on basal crystallographic planes (Fig. 1c, d, Fig. 2). Micrographs in the Fig. 2b and 2d show the same areas tilted by the angle of ≈60° (from -30° to +30° inclination of the goniometer). The same voids are marked by arrows. It is clearly seen that projection of the voids on the image plane changes from hexagonal faceted at ~+30° (Fig. 1c or Fig.2a,c) to the narrow rectangles at ~-30° (Fig. 1d or Fig.2b,d) [2].

Fig. 1. Gas bubbles in beryllium pebbles irradiated at 643 K (a, b) and at 713 K (c, d). The areas imaged in parts “a” and “c” are oriented near to the (0001)h zone axis and in parts “b” and “d” they are oriented along the zone axis perpendicular to the (0001)h direction.

EELS spectroscopy was used for detection and analysis of He and H2 gases trapped inside bubbles [3]. The number densities of both gases inside the bubbles were calculated using atomic scattering cross-section and the intensity of the zero-loss peak. The values He=(4.2±1) atoms/nm3 and nH2=(3.5±1.2) molecules/nm3 were determined for a bubble with a diameter of 160nm. The number densities of both gases increase with decreasing the bubble diameter.

Spherical second-phase precipitates formed at GBs and inside grains were observed at the two lowest (370°C and 440°C) irradiation temperatures only. EDX mapping reveal that precipitates inside grain and at the GB have increased iron and aluminum content suggesting formation of Fe-Al-Be phase. In the material irradiated at 440°C, most precipitates have also Fe-Al-Be composition, while several other single- and multi-phase precipitates were found. The Fe-Al-Be phase is observed as 10-15 nm precipitates inside grains and as 200 nm particle attached to a gas bubble at the GB. This suggests that stability of these precipitates decreases under irradiation and they dissolve at some temperature between 440-560°C.

Fig. 2. Gas bubbles in beryllium irradiated at 833 K (a, b) and 923 K (c, d). The areas imaged in “a” and “c” are oriented near to the (0001)h zone axis and those in “b” and “d” along the zone axis perpendicular to the (0001)h direction. Note that thicker bubbles obey pronounced faceting (see bubbles marked with arrows in 2c, d).

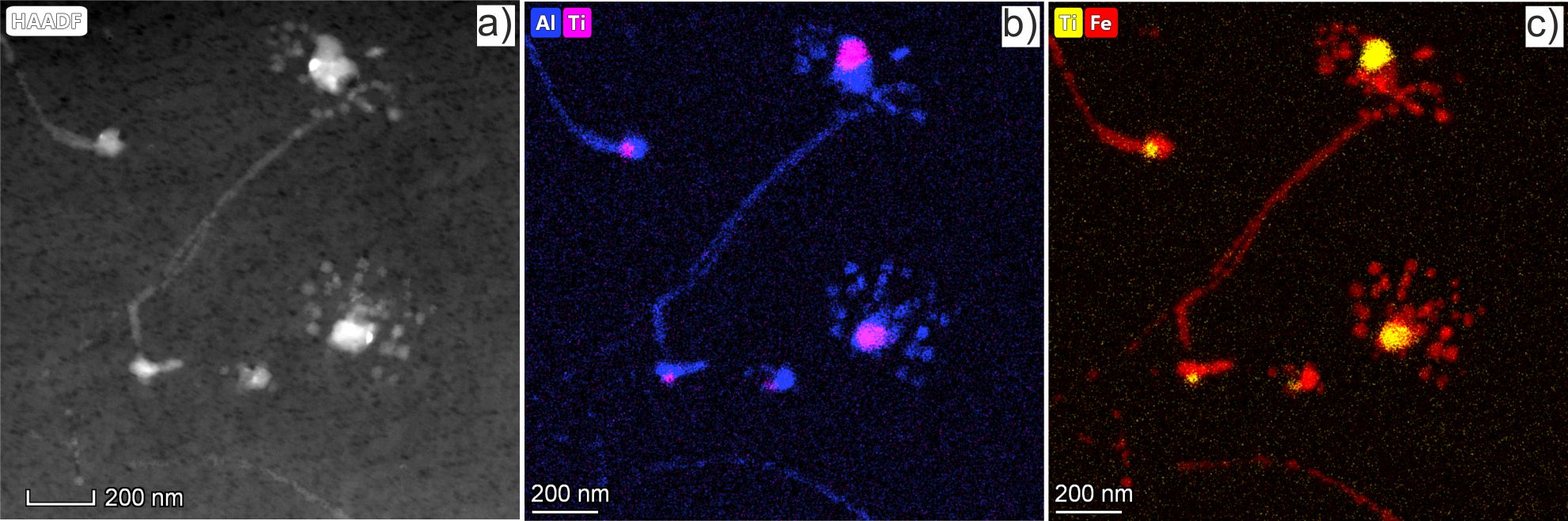

In fact, dissolution due to the recoil atoms induced by neutron irradiation followed by reprecipitation of complex-phase precipitates was observed at 480 °C. Fig. 3 shows two precipitates with sizes between 100-150 nm that are surrounded by numerous precipitates with sizes between 20-50 nm. The larger precipitates contain multiple phases of Al-Fe-Si-Cr-Ti-Mg-Mn-U elements, while the smaller precipitates contain a Fe-Al single phase. When a cascade of atomic collisions induced by neutron irradiation overlaps with a precipitate, its atoms can be ballistically knocked out into surrounding matrix leading to its dissolution. During irradiation, this process is balanced by the growth of the precipitate due to a constant flux of solute atoms to the precipitate.Fig. 3 Images show a radiation-induced dissolution of complex precipitation. The HAADF image is represented in part (a) and the 2D distribution of Al (blue) and Ti (magenta) as well as Ti (yellow) and Fe (red) are represented in parts (b) and (c) respectively.

The results of the present study allow conclusions regarding the application of beryllium in fusion technology

- References

[1] M. Klimenkov, et al Journal of Nuclear Materials 455 (2014) 660–664

[2] M. Klimenkov, et al Scientific Reports 2020 accepted

[2] M. Klimenkov et al. Micron 127 (2019) 102754