Structure of spin coated phase separated thin polymer films

- Abstract number

- 97

- Event

- European Microscopy Congress 2020

- DOI

- 10.22443/rms.emc2020.97

- Corresponding Email

- [email protected]

- Session

- PSA.6 - Geological Materials & Bio-mineral systems

- Authors

- Pierre Carmona (2, 1), Ass.Pr. Magnus Röding (2, 1), Pr. Aila Särkkä (1), Pr. Eva Olsson (1), Adj.Prof. Niklas Lorén (2, 1)

- Affiliations

-

1. Chalmers University of Technology

2. RISE Research Institute of Sweden

- Keywords

cellulose, confocal microscope, drug delivery, phase separation, spin coating

- Abstract text

Summary

Spin coating is a widely used technique for making uniform polymer films. In this work, we studied phase separation in thin hydroxypropylcellulose/ethylcellulose (HPC/EC) films made using spin coating, which is of interest for controlled drug release applications. We demonstrate that the system phase separates through the spinodal decomposition mechanism. Further, we show that the spin coating process influences the final film structure. The results show that, both phase-separated domain size and film thickness decrease with increasing spin speed.

Introduction

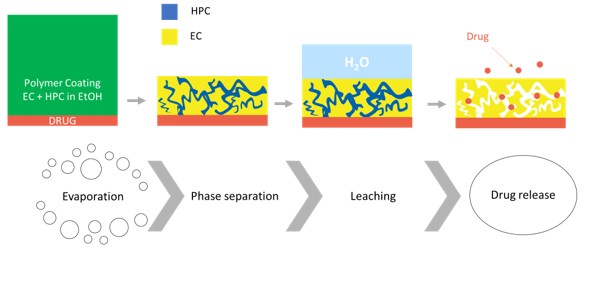

Controlled release formulations are used to deliver drugs at predetermined rates and periods of time in the body with the aim of increasing the efficiency and minimizing side effects. Coatings made of porous phase separated films are very effective for controlling mass transport out of pharmaceutical pellets [1], which is accomplished by tailoring the porous microstructure. Water-insoluble ethylcellulose (EC) and water-soluble hydroxypropylcellulose (HPC) form a one-phase polymer blend that can be mixed in a common solvent, e.g. ethanol. Phase separation occurs during solvent evaporation and a film is produced [2]. When in contact with water, HPC is leached out and a porous network is formed through which the drug is transported (Figure 1). In industrial production of pellets, a fluidized bed spraying process is used. In our work, spin coating was used to mimic the industrial spraying process. When spin coating the HPC/EC mixture on a glass substrate, a bicontinuous phase-separated structure was formed. Our aim was to investigate the influence of the spin coating process and the composition on the formed microstructure. Confocal laser scanning microscopy (CLSM) and image analysis were used to characterize the phase-separated film structure. Profilometry was used to determine the film thickness.

Figure 1. Formation of porous film made of HPC and EC for drug delivery. From left to right, the different steps: ethanol evaporation, phase separation and kinetic trapping, HPC leaching, and drug release

Materials and Methods

Solutions of HPC/EC with 4 different compositions (different ratios of HPC:EC in the polymer blend) were prepared: 6 wt% of polymer blend was mixed in a solution of 2 mM Na-fluorescein in ethanol (96%). The polymer ratios studied were 22:78, 30:70, 45:55 and 60:40 wt% of HPC and EC in the polymer blends. Na-fluorescein was used to stain the HPC phase. The HPC/EC films were made in the following manner. First, a drop of 250 µL of HPC/EC mixture was deposed on the surface of a glass microscope slide and a film was obtained by using a spin coater (WS-650MZ-23NPP, Laurell Technologies). The spin speed was varied in the range 1,000-10,000 RPM.

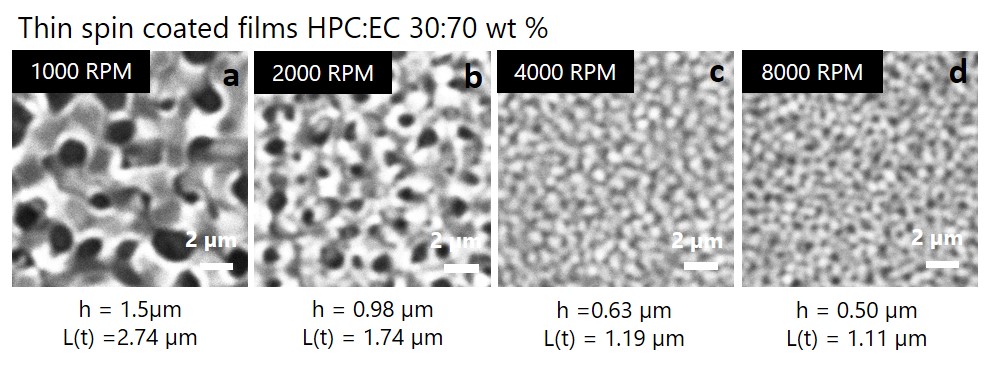

The structure of the spin coated thin films was determined using a Leica TCS SP5 CLSM upright microscope and an oil immersion objective with magnification 100x and numerical aperture NA=1.4. The light source was a 488nm argon laser and the signal at the maximum of emission for fluorescein (500 to 600 nm) was recorded. On the micrograph, the bright phase corresponds to HPC phase and the dark phase to EC phase.

In order to extract information from the micrographs, we performed image analysis using the two-dimensional fast Fourier Transform (2D-FFT).

To determine the thickness of the spin-coated films, a stylus profilometer (KLA Tencor D-100) was utilized.

More details can be found in Carmona et al. manuscript [3].

Results and Discussion

Figure 2 shows CLSM micrographs of spin coated films with 30wt% HPC. The characteristic length scale as a function of time t of the spinodal decomposition pattern was plotted versus the thickness h of the film. We found that the domain size is increasing with the average thickness of the film. This result agrees with results from other spin coated polymer systems [4-6]. When the film is thinner, the evaporation is faster, because less solvent has to evaporate, and the surface-to-volume ratio is higher which accelerates the evaporation further. When the evaporation is faster, the phase separation occurs at an earlier stage, leading to thinner films having shorter characteristic length scales. Spin curves i.e. film thickness versus spin speed were fitted with a power law as described by the Meyerhofer model [7], and the exponent was found to be close to -0.5. In addition, a linear relationship between L(t) and the thickness was established for polymer blends with 22 wt%, 30 wt% and 45 wt% HPC [3].Figure 2. a,b,c,d) Micrographs (magnification 1100x, field of view 14 µm) of a spin coated film of HPC 30wt%, with spin speeds, film thickness and characteristic wavelength being a) 1000 RPM, h=1.5 µm, L = 2.74 µm) b) 2000 RPM , h=0.98 µm, 1.74 µm c) 4000 RPM , h=0.63 µm, L= 1.19 µm d) 8000 RPM, h=0.50 µm, L= 1.11 µm

Conclusion

The effect of spin coating parameters on the final structure of phase-separated spin coated HPC/EC films, as a function of composition (ratio HPC:EC) was determined using CLSM. A Fourier image analysis method was developed to determine the typical length scale of the domain phases. The thickness was correlated with spin speed to create spin curves for each studied composition. It was found that the final domain size and the film thickness both decrease when the spin speed increases. These findings provide a good basis towards tailoring the microstructure of thin HPC/EC films and controlling their mass transport properties. The next step in our work is to perform in situ measurements with CLSM to understand the phase separation kinetics.

- References

[1] Marucci, M. et al, Int J Pharm 411(1-2) (2011), p. 43-8.

[2] Andersson, H. et al, Int J Pharm 511(1) (2016), p. 223-235.

[3] Carmona, P. et al, RISE Research Institute of Sweden, Gothenburg (2020), Unpublished Manuscript.

[4] Williams, E.L. et al, RSC Advances 3 (2013), p.43

[5] van Franeker, J.J. et al, Advanced Functional Materials 25(6) (2015), p. 855-863.

[6] Muller-Buschbaum, P. and M. Stamm, Colloid Polymer Science 279 (2001), p. 376-381.

[7] Meyerhofer, D., J. Appl. Phys. 49 (1978), p. 3993–3997.

[8] The authors gratefully acknowledge funding from the Swedish Foundation for Strategic Research (SSF grant FID16-0013). Christian Von Corswant and Anna Olsson from Astra Zeneca are acknowledged for valuable and fruitful discussions. Christian Müller and Sandra Hutmark from the Department of Chemistry of Chalmers University are acknowledged for access to lab facilities (spin coater and profilometer), for help and useful advice.