Studying the genesis of nickel catalysts with in situ gas phase TEM

- Abstract number

- 376

- Event

- European Microscopy Congress 2020

- DOI

- 10.22443/rms.emc2020.376

- Corresponding Email

- [email protected]

- Session

- PST.6 - In-situ and in-operando microscopy

- Authors

- Savannah Turner (2), Irina Yarulina (1), Bernard Reesink (1), Prof Krijn de Jong (2)

- Affiliations

-

1. BASF

2. Utrecht University

- Keywords

catalyst

environmental

gas

in situ

synthesis

- Abstract text

The activity, stability, and selectivity, of heterogeneous catalysts are largely determined by their preparation. Finding analysis techniques that allow the study of catalysts during synthesis while simultaneously providing detailed structural and chemical information is a challenge that has been the focus of a large amount of research [1]. Transmission electron microscopy (TEM) is a technique which can provide the desired nanoscale information however it has the drawback that it requires ultra-high vacuum conditions to obtain high resolution images. Although historically it was predominantly limited to studying catalysts before and after reactions, new hermetically closed cell systems now enable both liquid and gas at atmospheric pressures to be introduced around the sample at a wide range of temperatures [2]. This paper presents an example of how this technique can be used to obtain greater insight into the processes taking place during catalyst synthesis.

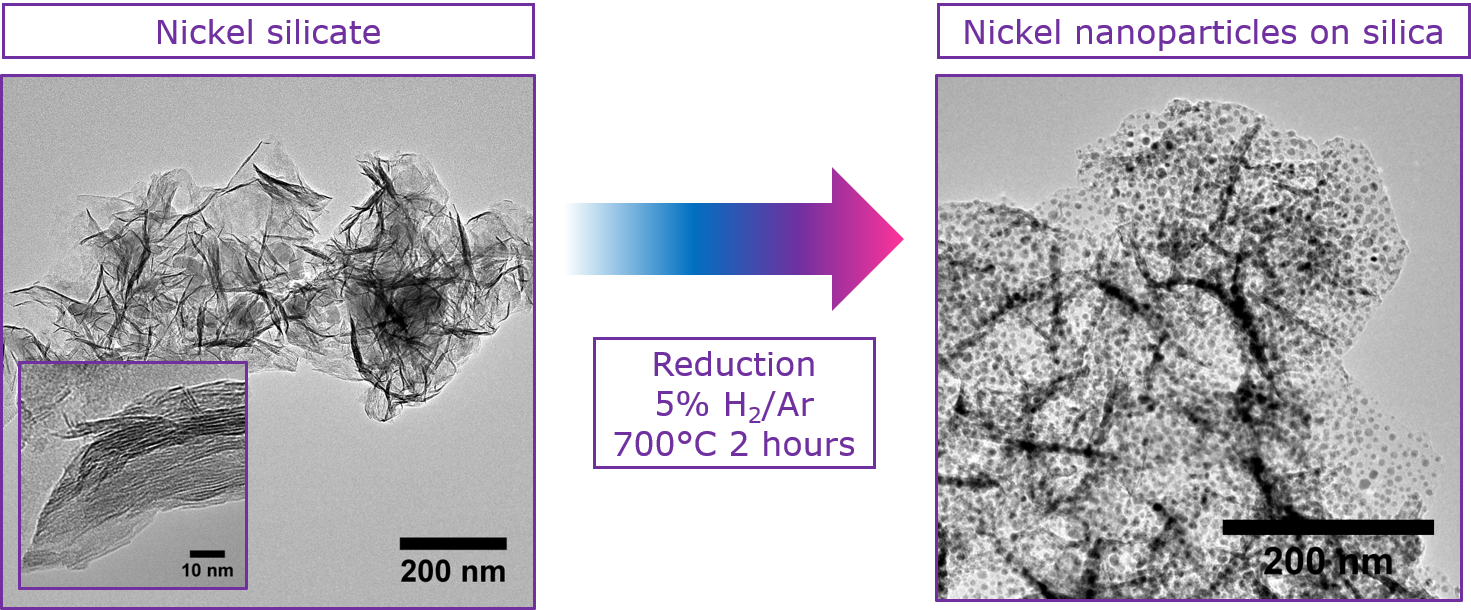

An important step in the synthesis of supported metal catalysts is the reduction of the metal precursor to the active metal nanoparticles. The conditions under which this step is carried out often determines the size and distribution of the nanoparticles on the support [3]. Nickel phyllosilicates are a commonly studied model catalyst precursor since after reduction they form well dispersed nickel particles supported on the silica with a narrow size distribution (Figure 1). Thanks to the homogeneity of this model system, the influence of the beam can be investigated by comparing the particle sizes after reduction in situ and ex situ as well as in irradiated and non-irradiated areas. After establishing the reliability of the experimental method, in situ reduction could be performed, and the particle growth tracked in real time.

Figure 1 TEM images of the nickel silicate catalyst precursor before reduction (left) and the nickel nanoparticles supported on silica after the ex situ reduction process (right).

In this study, 30 wt.% Ni/SiO2 was prepared using deposition precipitation in the presence of urea. The material was calcined at 500°C and characterized ex situ using powder x-ray diffraction (pXRD), temperature programmed reduction (TPR), thermogravimetric analysis (TGA), nitrogen physisorption and TEM. In situ experiments were performed using a Protochips Atmosphere gas delivery system and a Talos F200X (FEI, 200 kV) operated in TEM mode using electron doses of under 25 e-.Å-2.s-1.

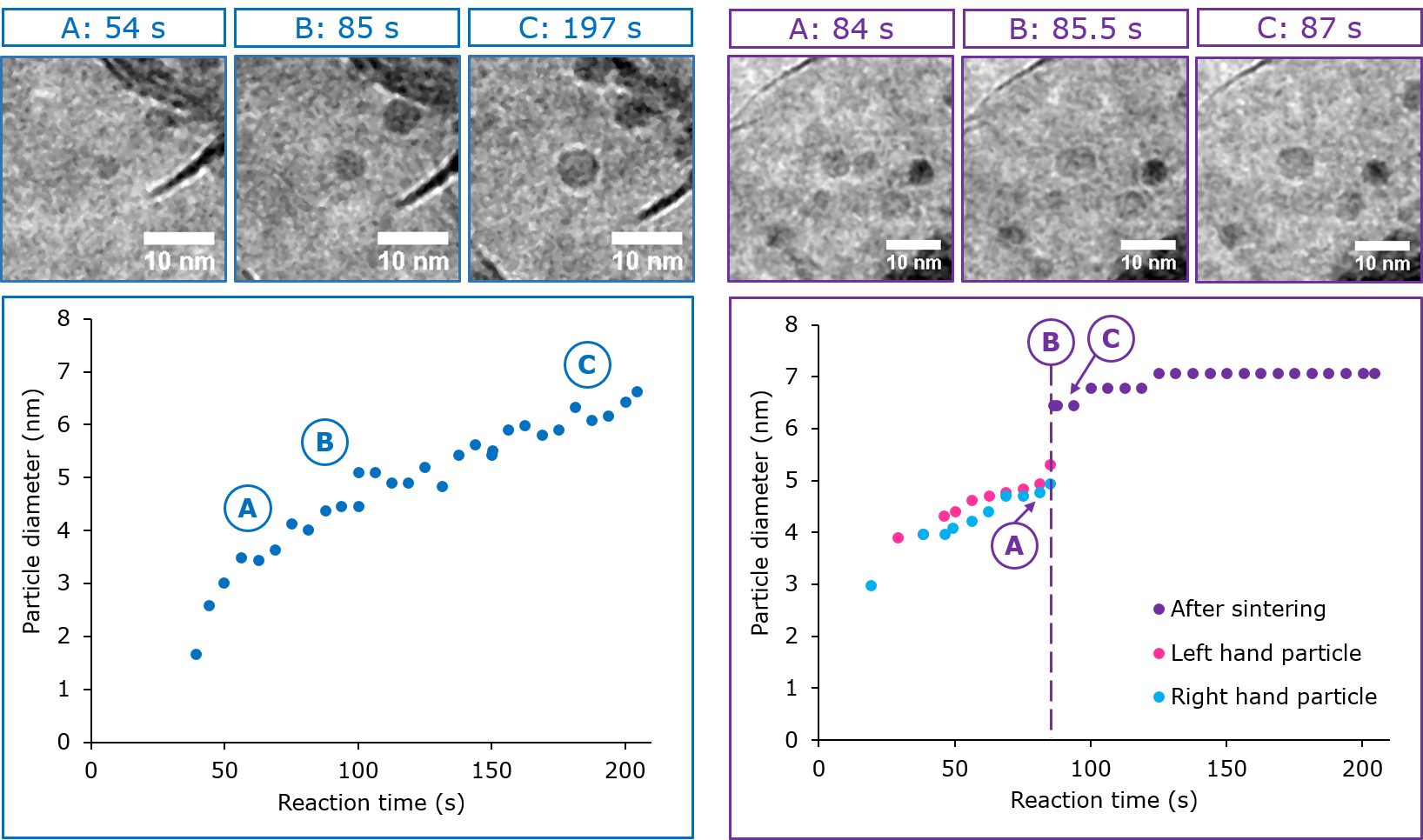

Stability experiments established that although irradiation can trigger early nucleation at low temperatures, at high temperatures the electron beam has a negligible effect on the particle size, particle distribution and extent of reduction. At 500°C under 1 bar H2/Ar and a 0.1 sccm flow rate, in situ reduction in the TEM was used to follow the particle growth in real time and comparison with non-irradiated areas showed that the kinetics of the reaction are unaffected by the electron beam. The particle sizes were measured as a function of time and it was found that although the majority of particles grow steadily, a number of them exhibit stepwise growth due to Particle Diffusion and Coalescence (PDC) (Figure 2). Whether or not a particle experiences this stepwise growth has little bearing on the final particle size.

Modelling the particle growth enables the study of the reduction kinetics at the nanoscale for this industrially relevant catalyst precursor. This kinetic information is compared with ex situ experiments using TPR and TGA at the macroscale in the full paper. This study demonstrates the added value that in situ TEM can bring to the field of catalyst preparation.

Figure 2 TEM images taken during in-situ reduction at 500°C under 5% H2/Ar with a 0.1 sccm flow and associated particle growth plots of a particle undergoing steady growth (left) and a particle undergoing stepwise growth (right).

- References

[1] H Topsoe, Journal of Catalysis, 216, (2003) p. 155.

[2] N De Jonge, W Bigelow, and G Veith, Nano Letters 10 (2010) p. 1028.

[3] P Munnik, P de Jongh, and KP de Jong, Chemical Reviews 14 (2015) p. 6687.