TEM observation and in situ compression tests of transition alumina prepared by high pressure compaction at room temperature

- Abstract number

- 891

- Event

- European Microscopy Congress 2020

- DOI

- 10.22443/rms.emc2020.891

- Corresponding Email

- [email protected]

- Session

- PSA.8 - Microscopy in industrial applications

- Authors

- Dr Lucile Joly-Pottuz (1), Dr Agnieszka Krawczynska (3), Dr Tomasz Plocinski (3), Dr Vincent Garnier (1), Dr Sylvie Le Floch (2), Dr Denis Machon (2), Pr Karine Masenelli-Varlot (1)

- Affiliations

-

1. Université de Lyon, INSA-Lyon, MATEIS CNRS UMR5510

2. Université de Lyon, UCB Lyon 1 ILM CNRS UMR5306

3. Warsaw University of Technology, Faculty of Materials Science and Engineering

- Keywords

ceramic materials

focused ion beam

in situ nanocompression

plasticity

transmission electron microscopy

- Abstract text

The behavior of ceramics at the nanometer scale strongly differs from the one of the corresponding bulk material. For instance, strong plastic deformation has recently been reported in isolated nanometer-sized alumina nanoparticles or MgO nanocubes, when tested in situ in a transmission electron microscope (TEM). This plastic behavior may also occur in a powder during the compaction process, even at room temperature. Controlling plastic deformation of nanoparticles during the ceramics processing might be a way to enhance their properties or to improve the processing route (compaction and sintering steps, for instance). The nanoparticle surface chemistry may also have an effect on the interaction between particles and thus on the deformation mechanism. We present here a comprehensive study of the mechanical behavior of transition alumina in the compacted powder and of the mechanical behavior of thin foils extracted from the compacted powder.

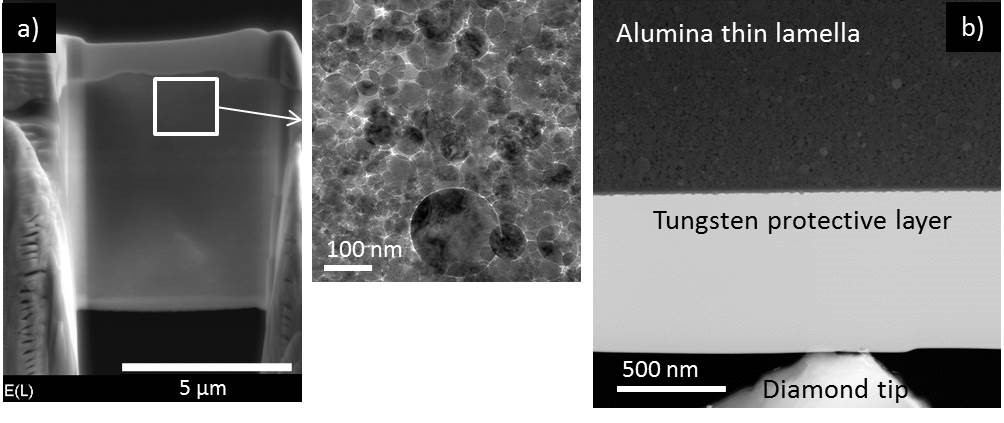

Transition alumina nanoparticles stored under different conditions were compacted at room temperature under different uniaxial pressures (5 GPa, 15 GPa and 20 GPa) in a diamond anvil cell or in a Paris-Edimbourg press. Thin foils of these compacted powders were prepared by Focused Ion Beam (FIB) machining and analysed by TEM (figure 1a). The thin foil geometry was optimized to perform in situ nancompression testing afterwards (Figure 1b).

Figure 1: a) alumina thin lamella prepared by FIB milling, b) alumina thin lamella during in situ nanocompression experiment in TEM observed in STEM mode

HRTEM observations and diffraction patterns analyses unambiguously revealed that nanoparticles underwent plastic deformation in the compacted powder. A study of these HRTEM images coupled with Fast Fourier transforms to get the associated diffraction patterns show that the deformation involves the {110} lattice planes, and the slip system {111} <110>. These observations are in agreement with the deformation observed on a single nanoparticle during in situ nanocompression tests inside a TEM. Moreover at high pressure, phase transformation can be evidenced.

In situ nanocompression testing of the thin foils revealed different behavior depending on the storage of the initial alumina powder used for compaction. Several imaging conditions were investigated to follow the nanoparticle movement and/or their deformation during the compression. This study reveals the interest of analyzing the deformation mechanism of alumina and the interaction of alumina nanoparticles during compaction process to optimize the compaction process, which is an essential step of the processing of ceramic materials.